Written by Natesh Narain

on

on

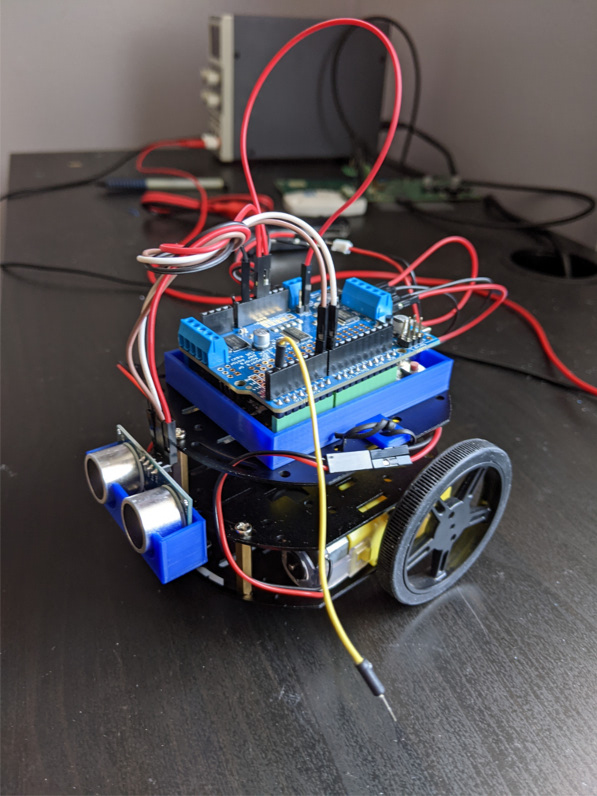

Stackbot 1

It’s a long weekend and I figured I’d throw together a little robot.

The main body is just from a robot kit I got from Adafruit.

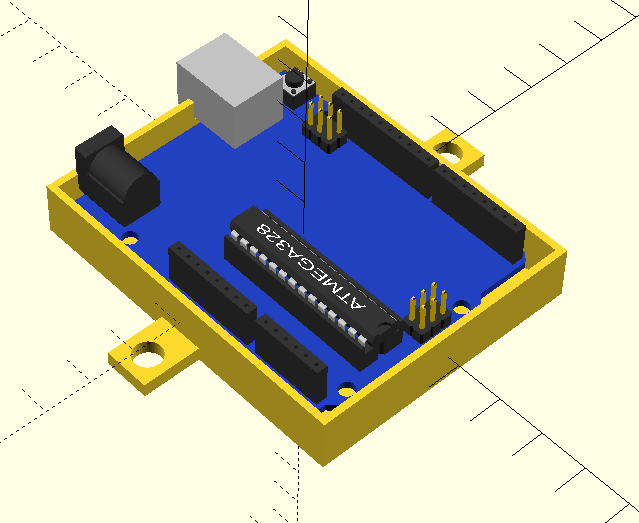

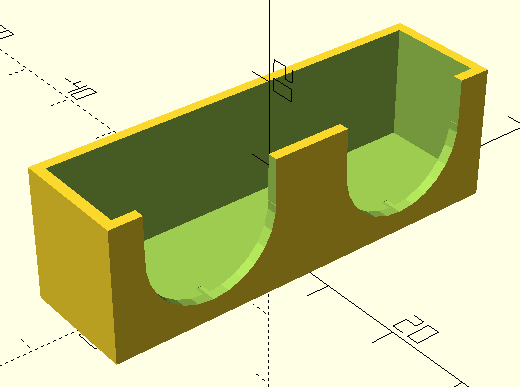

The top disk has an Arduino UNO + Motor Shield sitting in a 3D printed holder. The front has a HCSR04 ultrasonic sensor also sitting in a 3D printed holder.

There’s a LiPo battery taped to the middle section.

3D Printed Parts

The UNO holder makes use of the vitamins provided by nopscadlib:

include <NopSCADlib/lib.scad>

include <BOSL/constants.scad>

include <BOSL/transforms.scad>

use <BOSL/shapes.scad>

include <NopSCADlib/vitamins/pcbs.scad>

PCB = ArduinoUno3;

pcb_shell_clearance = 3;

shell_thickess = 3;

mount_height = 10;

interface_length = 80;

interface_width = 50;

module arduino_uno_mount(pcb) {

dims = pcb_size(pcb);

inner_x = dims[0] + pcb_shell_clearance;

outer_x = inner_x + shell_thickess;

inner_y = dims[1] + pcb_shell_clearance;

outer_y = inner_y + shell_thickess;

outer_z = dims[2] + mount_height;

interface_length = outer_x + 10;

interface_height = 3;

difference() {

union() {

cube(size=[outer_x, outer_y, outer_z], center=true);

difference() {

zmove(-(outer_z/2) + (interface_height/2)) cube(size=[10, interface_length, interface_height], center=true);

mount_hole_radius = 3;

ymove((interface_length /2) - mount_hole_radius - 2) cylinder(r=mount_hole_radius, h=50, center=true);

ymove(-(interface_length /2) + (mount_hole_radius + 2)) cylinder(r=mount_hole_radius, h=50, center=true);

}

}

union() {

zmove(dims[2]) cube(size=[inner_x, inner_y, outer_z], center=true);

pcb_cutouts(pcb);

}

}

}

module base_stl() {

stl("base");

arduino_uno_mount(PCB);

}

module main_assembly() {

assembly("main") {

render()

base_stl();

pcb(PCB);

}

}

if ($preview) {

main_assembly();

}

The ultra sonic sensor:

include <BOSL/constants.scad>

include <BOSL/transforms.scad>

use <BOSL/shapes.scad>

sensor_dims = [10, 45.5, 16];

transceiver_radius = 16.1 / 2;

transceiver_edge_offset = 10;

attachment_size = 10;

attachment_thickness = 2;

attachment_hole_size = (3 / 2) * 1.4;

shell_thickess = 2.5;

clearance = 1.5;

b = 0.01;

module mount() {

inner_x = sensor_dims[0] + clearance;

inner_y = sensor_dims[1] + clearance;

outer_x = inner_x + shell_thickess;

outer_y = inner_y + shell_thickess;

ix = inner_x / 2;

iy = inner_y / 2;

ox = outer_x / 2;

oy = outer_y / 2;

z = sensor_dims[2];

union() {

difference() {

// Initial box to enclose the sensor

span_cube([-ox, ox], [-oy, oy], [0, z]);

// Hollow area for the sensor

zmove(shell_thickess) span_cube([-ix, ix], [-iy, iy], [0, z]);

// Room for the sensor transmitter and reciever

cutout_left_offset = -(sensor_dims[1] / 2) + transceiver_edge_offset;

cutout_right_offset = (sensor_dims[1] / 2) - transceiver_edge_offset;

translate([ox, cutout_left_offset, (z / 2) + shell_thickess])

yrot(90) cylinder(r=transceiver_radius, h=shell_thickess * 2, center=true);

span_cube([ix-b, ox+b], [cutout_left_offset - transceiver_radius, cutout_left_offset + transceiver_radius], [(z / 2) + shell_thickess, z+b]);

translate([ox, cutout_right_offset, (z / 2) + shell_thickess])

yrot(90) cylinder(r=transceiver_radius, h=shell_thickess * 2, center=true);

span_cube([ix-b, ox+b], [cutout_right_offset - transceiver_radius, cutout_right_offset + transceiver_radius], [(z / 2) + shell_thickess, z+b]);

}

difference() {

span_cube([-ox, -ox - attachment_size], [-attachment_size/2, attachment_size/2], [0, attachment_thickness]);

xmove(-ox - attachment_size / 2) cylinder(r=attachment_hole_size, h=attachment_thickness * 5, center=true, $fn=50);

}

}

}

mount();

Quick and dirty. Still embracing OpenSCAD.

Firmware

This uses FTL from my last post.

// TODO: make generic

#include <avr/interrupt.h>

#include <ftl/logging/logger.hpp>

#include <ftl/comms/uart.hpp>

#include <ftl/drivers/adafruit/motor_shield.hpp>

#include <ftl/drivers/sensors/hcsr04.hpp>

#include <ftl/platform/avr/interfaces/timer.hpp>

#include <ftl/platform/platform.hpp>

#include <new>

#define DISTANCE_THRESHOLD 0.2

#define TURN_DELAY_MS 2000

using Hardware = ftl::platform::Hardware;

class SystemHardware

{

public:

SystemHardware()

: motors_{0x70}

{

};

bool initialize()

{

// Initialize I2C

Hardware::I2C0::initialize(ftl::comms::i2c::ClockMode::Fast);

// Initialize motor driver

if (!motors_.initialize(1000))

{

return false;

}

motors_.setSpeed(0, 0.5);

motors_.setSpeed(1, 0.5);

// Enable interrupts

sei();

return true;

}

void driveForward()

{

motors_.forward(0);

motors_.forward(1);

}

void turnLeft()

{

motors_.backward(0);

motors_.forward(1);

}

void turnRight()

{

motors_.forward(0);

motors_.backward(1);

}

float readForwardRange()

{

return range_.read();

}

private:

ftl::drivers::MotorShield<Hardware::I2C0> motors_;

ftl::drivers::Hcsr04<Hardware::GPIOD<7>, Hardware::InputCapture1, Hardware::Timer> range_;

};

enum class DriveState

{

Driving, Turning,

};

ftl::logging::Logger<Hardware::UART0> logger{ftl::comms::uart::BaudRate::Rate_9600};

SystemHardware hw;

int main()

{

ftl::logging::SystemLogger::instance().setLogger(&logger);

if (!hw.initialize())

{

LOG_ERROR("failed to initialize system hardware");

for(;;);

}

DriveState state = DriveState::Driving;

for(;;)

{

const auto range = hw.readForwardRange();

if (state == DriveState::Driving)

{

hw.driveForward();

if (range >= -1.0 && range < DISTANCE_THRESHOLD)

{

if (ftl::timerOverflow() % 2)

{

hw.turnRight();

}

else

{

hw.turnLeft();

}

state = DriveState::Turning;

}

}

else if (state == DriveState::Turning)

{

if (range > DISTANCE_THRESHOLD || range < 0)

{

state = DriveState::Driving;

}

}

LOG_INFO("range: %02.04f", range);

Hardware::Timer::delayMs(100);

}

return 0;

}

Just drivers around until the sensor detects something.

Connected Posts

1 post references this page